Project Type: Co-op

Duration: July 2021

Skills Used: SolidWorks CAD, GD&T

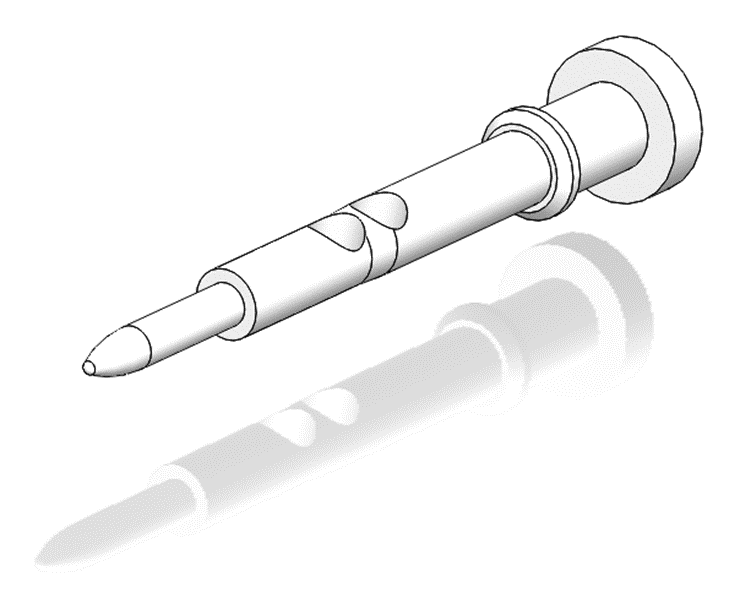

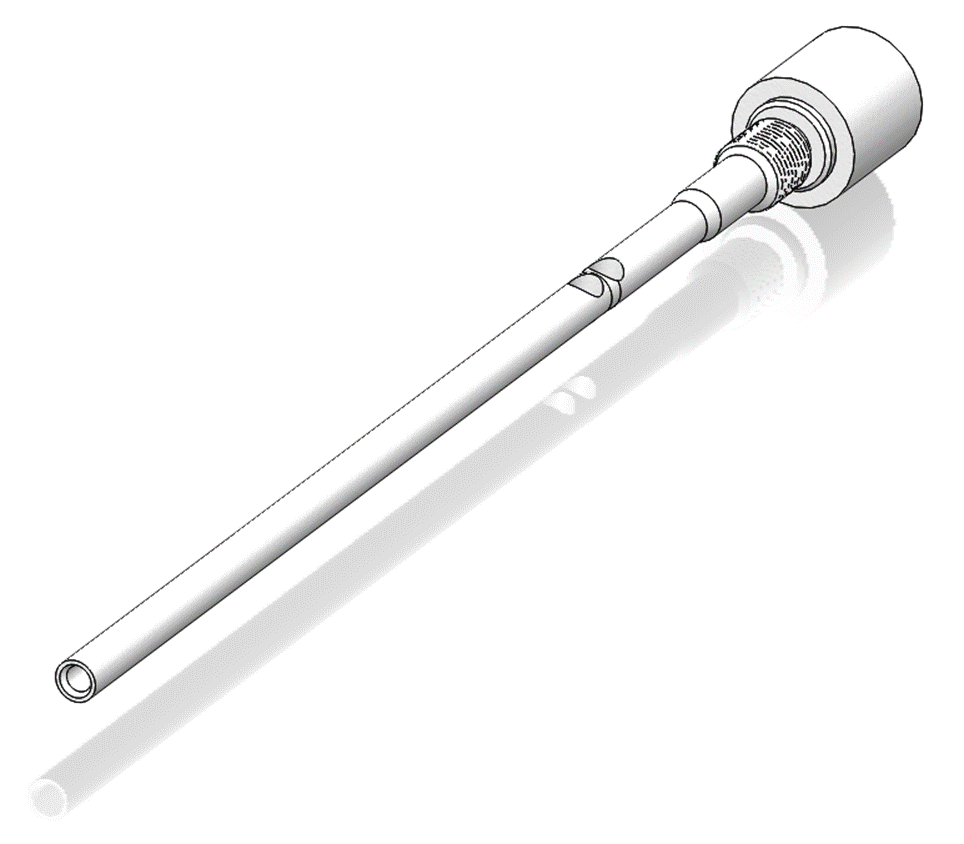

Description: Gauge rod used in replacement of a leadscrew to precisely mount carriage blocks onto stereo imager lens barrel

Challenges:

- Attempt to create single tool to be used for two asymmetric sides of equal length

- Design a method of mounting to lens barrel to correctly align and install rail carriages

- Incorporate tight tolerances (~50 micron in places) for precision alignment

- Model the part in a clear, concise manner

Solutions:

- Created two part splitting design with center sliding alignment pin

- Used motor mount threads and wave spring as one point of mounting

- Used datums in lens barrel to create concentric alignment

- Through holes for each screw to be tightened for both sides

- Toleranced to sliding fit along concentric parts (pin, datums)

- Modeled using single revolve along a center axis

Results:

- Stainless steel tool properly modeled, toleranced, and drawn

- Revised to different specifications following change of plans, no longer using one tool for both sides

Learnings:

- GD&T conventions and when to properly use callouts in concentric models

- Designing parts in larger assemblies to reference dimensions of already-established components

Additional Images: