Project Type: Co-op

Duration: September-November 2020

Skills Used: SolidWorks, Hand Fabrication, Vendor Interaction

Description: Small noise isolating chamber used to record cordless vacuum sounds. Used during COVID-19 pandemic to not only share noise files digitally but to analyze acoustic changes across products.

Diagram of inner parts of chamber.

Challenges:

- Keep costs low compared to anechoic chambers on the market while maintaining best performance

- Allow range of products to be tested inside using controlled parameters

- Gather data and observations to be shared to remote employees

Solutions:

- Research led to use of MDF and noise-isolating foam in construction

- Interchangeable floor and pass-through for various wand and nozzle combinations

- WiFi camera and USB microphone pass-through to record data and video

Results:

- Reduced initial proposal cost from ~$3000 to ~$600 with still useable performance

- Designed to be able to roll on rubber casters and fit through standard door frame

- Designed to be adaptable for different testing scenarios

Additional Images:

chamber with test unit in place

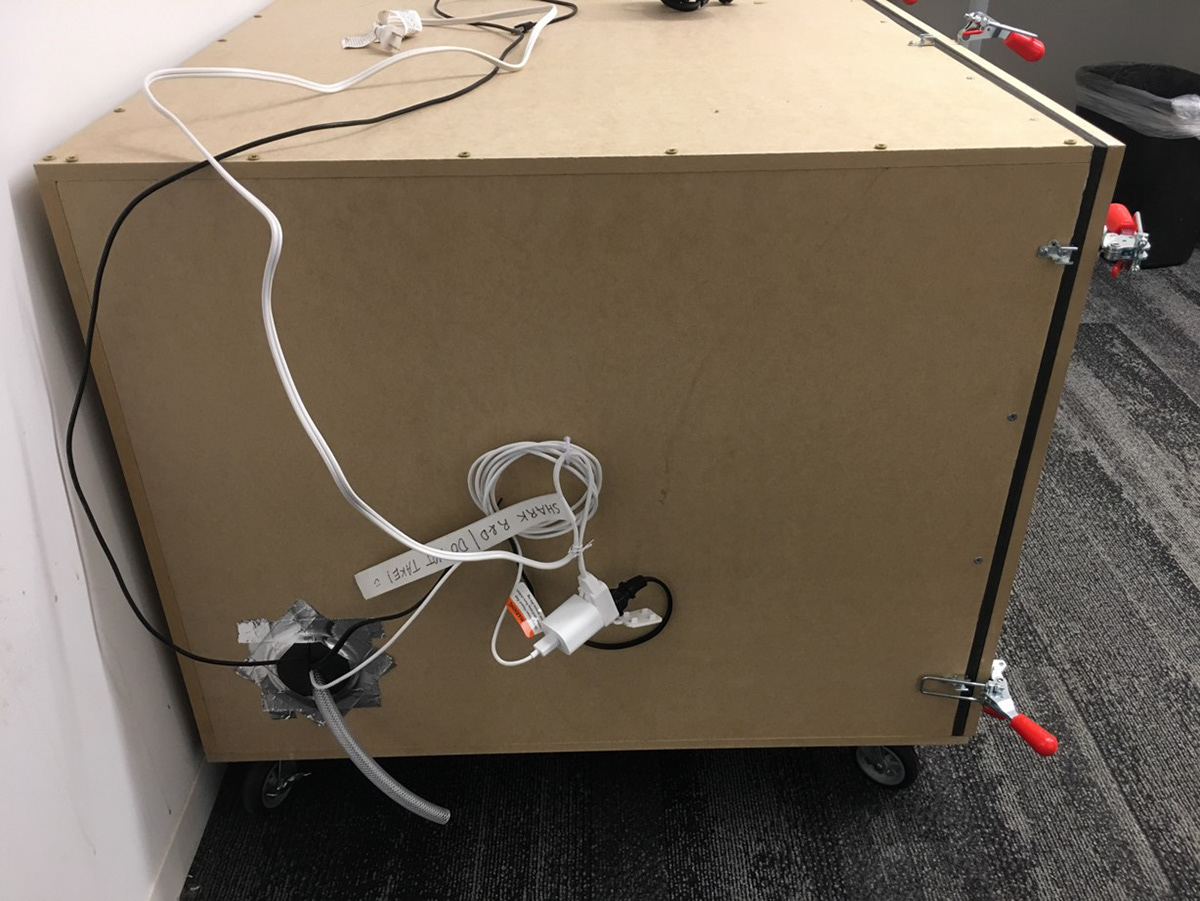

outer enclosure without foam

feed capture from Amazon cloud cam

quarter view of test unit in place

vacuum wand pass through before hole cut

gasket of wand pass through

test unit inserted into chamber